Lean Management is one way in which the principles of the lean philosophy can be applied to your organisation. Lean is not to be seen as a finite and fixed item, but is a state of operation and culture made up of many parts.

Lean Management is one way in which the principles of the lean philosophy can be applied to your organisation. Lean is not to be seen as a finite and fixed item, but is a state of operation and culture made up of many parts.

The beginning of Lean Management is generally accepted to have been derived from the Toyota Production System as developed by Taiichi Ohno and others over a forty year period. Initially it began with efforts to reduce die change time on a press, which then allowed for a reduction of in-process inventory – and that became just-in-time (JIT) management. This meant the need for less warehouse space, and related equipment. When the flow of work is interruption free, waste is more easily eliminated.

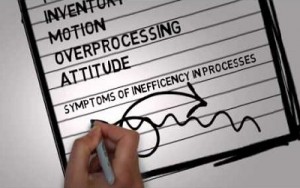

Lean is the elimination of waste. More importantly, lean is continuous improvement in all work processes.

People

In order to improve the work, you can ask your people to think, and challenge them to innovate and find ways to speed processes by eliminating unnecessary activities. Your front line people, who are often the greatest experts in their work, can experiment, watch the data, and learn from the facts.

Process

This model of improving the work process by those who do the work is the essence of lean management. It is management that observes, encourages, challenges, and learns. The goal is to have management that gathers facts, encourages experimentation, and spreads best practices. Lean is a moving target because, it is a process of learning and improvement. It can be seen as a culture and philosophy rather than a particular method or technique.

Management

Indicators of a lean management approach include:

- Lean is a culture of continuous improvement.

- Lean is the application of experimentation and work processes to find improvements.

- Lean is respect for people, for those who do the work.

- Lean is the elimination of waste in all its forms.

- Lean assures the quality and safety of all work for both customers and staff.

- Lean is a focus on improving the process and not on blaming people.

- Lean is a culture of teamwork.

- Lean is a culture that returns the satisfaction and fun to work.

- Lean is an interruption-free process flow.

At IiE we specialise in the use of Lean to improve the efficiency of management and operations within your organisation. Contact us to find out more about how we have helped our customers in a variety of business sectors.